Falcon Winch Assist

The Falcon Winch Assist is the only Hydraulic Winch Machine on the market that provides your crew with safety, simplicity, productivity and real versatility.

Removing the instability out of steep-slope logging

We believe you shouldn’t have to put your life at risk to get a job done well. We also believe in simplicity. So, when we designed the Falcon Winch Assist we focused on what matters. Safety and production are at the forefront of every Falcon Winch Assist which is why you’ll see a user-friendly interface, a one rope tethering system and the versatility of the excavator all at the turn of a key.

“Some of the spots I wouldn't of even gone down - We would of slid for starters but there would have been a lot of manual falling that would've had to of been done."

Bing

Felling Machine Operator, Diack Contracting

Product overview

The industry leading, practical features of the Falcon Winch Assist deliver safer, more efficient contract logging even on the toughest sites.

Multiple Safety Features

The Falcon Winch Assist has been designed and tested through thousands of operational hours in a wide range of slope and soil conditions. As a result, we’ve developed a number of safety features to eliminate operator risk.

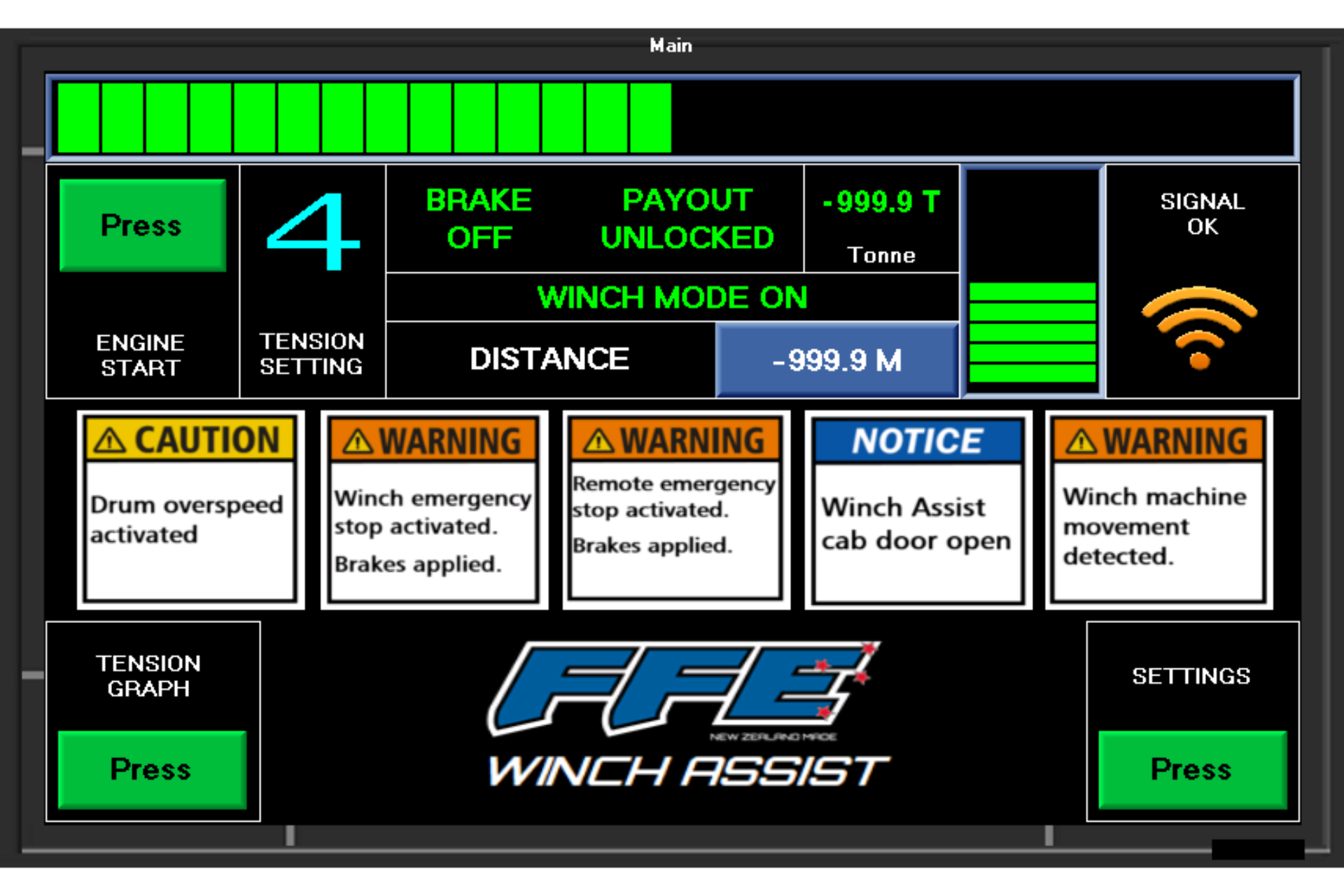

- Overspeed Alarm triggering a rope management system in the Winch which automatically tensions the rope to reduce the speed, and notifies the operator to slow down

- Dual multiplate brakes on each end of the drum

- Movement Alarm to alert the operator if the Winch Machine experiences any movement.

- Cab Door Tamper Detection Alarm.

- Remote & local E-stops to shut the Winch Assist down in case of an emergency

- Over Tension Alarms.

- Drum Over Speed Alarm/Arrest.

- Maximum Rope Pay Out Alarm/Arrest.

- Live Feed Camera System for the Operator monitoring the engine bay and winch drum.

Simplicity Of Operation

Developed in the forest with collaboration from logging crews every step of the way means the single rope Falcon Winch Assist is engineered to be uncomplicated, simple to operate and easy to maintain.

- The Tethered Machine Operator only has one rope to manage when operating down the slope reducing complexity and potential for snags.

- The Winch System design provides less mechanical and electrical complexity and therefore opportunity for faults and breakdowns.

- The Winch Unit is enclosed by rear guarding for protection with easy access points for maintenance.

Large Rope Size For Greater Safety

The Falcon Winch Assist uses the largest rope size of any Winch Assist machine currently on the market. At 1 ⅛ inch (28mm) diameter the swaged rope provides 69 tonnes of breaking strength ensuring that even shock loading will not compromise the strength or structural integrity of the rope.

- Falcon Winch Assist 1 1/8" rope has a 23-tonne safe working load (the Falcon Winch Assist itself has a 21-tonne working load limit)

- Larger ropes equate to longer rope life as they are more resistant to mechanical damage.

Versatility On The Skid

The Falcon Winch Assist is designed to allow logging contractors to use it as a multi purpose machine. The Falcon system has minimal impact on the original specifications and performance of the base excavator. It comes with the option of a quick hitch so it can also operate as a loader, conventional digger or as a loader or shovelling machine.

- On a 30 tonne carrier, the weight of the complete Winch Unit is comparable to the original counter weight.

- With only an additional 600mm of length to the counterweight, the machine performance is very similar to the original.

Specifications

Frequently asked questions (FAQ)

We use all major brands for base machines globally. The machine must meet criteria consisting of weight must be 30T or more and a hydraulic oil flow of 400L/min or more.

We have many different payment options from purchase outright to leasing. Please contact us to find out what payment terms are best suited for you.

Depending on what base machine is used and what guarding option is chosen, it will potentially add up to 4T over original base machine weight.

Yes, this can be specified with many optional extras including quick hitch, rotating grapple & plumbing, high & wide, guarding package and more.

Yes we do. Please ask your sales rep for extra information.

Yes, full training will be provided during the commissioning of the machine, however additional specific training can be arranged. We do not leave the site until you’re confident on operating the Falcon Winch Assist.

First, reach out and tell us about your operation. If we mutually agree a Falcon Winch Assist is beneficial to your operation we then outline finer details. We use a personalised client-by-client approach for our Falcon products to ensure you have the information you need, when you need it that’s best communicated in way that’s convenient to you.

Yes, all Falcon Winch Assist parts & components are kept in stock at DC Equipment approved distributors.

We have dedicated service team members across the country coupled with technical support to keep you working stress free.

We have dedicated service team members across the country coupled with technical support to keep you working stress free . We have well trained service technicians globally which are backed up by a support network in New Zealand.

This is dependent on the tension setting and the working distance from the Winch Assist.

The maximum operating angle of any traction assisted tethered machine is 45 degrees or 100% from the top of the slope to the bottom of the slope.

The Falcon Winch Assist uses 1’ 1/8” Inch rope.

Find a distributor

You can find our range of forestry equipment from selected suppliers in New Zealand, Canada, the United States and Chile.

Case study

Diack Contracting

Falcon Winch Assisted Felling in Gisborne

Request a call back

The Falcon Winch Assist has been designed and tested through thousands of operational hours in a wide range of slope and soil conditions. As a result we’ve developed a number of safety features to eliminate operator risk.